Note: This blog post is part of a five-part series called “Toward a Circular Supply Chain: Shifts in SCOR Supply Chain Habits.” Keep an eye out for future posts.

Imagine: All waste and process by-products in the world will become the raw materials and inputs needed by all the processes in the world. In turn, the maintenance, refurbishment and remanufacturing industries will dramatically increase in size and value. Then, aftermarket supply chains will become the dominant model as linear supply chains give way to circular supply chains.

In the circular economy, materials and resources loop throughout processes indefinitely. Supply and demand loops among value networks allow for types of monetization that were previously impossible. On a global scale, this circular economy is expected to add $4.5 trillion to the global economy by 2030.

Supply chains around the world will be challenged to shift their habits to support new business models. The increased complexity that will be managed by global supply chains will be represented by future Supply Chain Operations Reference (SCOR) model versions.

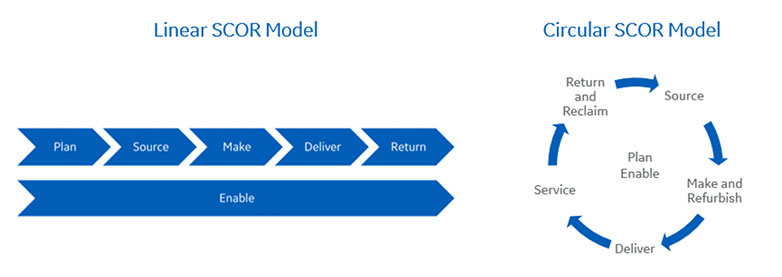

SCOR processes shift from linear to circular

The supply chain processes in the SCOR model may be the most widely recognized and leveraged part of the reference model. A shift from linear SCOR processes to circular SCOR processes will impact the relationship among the processes. Although bending a linear process graphic into a circle is hardly revolutionary, the work it will take to enable this process flow to happen certainly is.

Shifts in existing processes will happen over time but undoubtedly will affect the entire model. Imagine, for example, the shifts that will come to the Source processes. Instead of tracking commodity markets, tomorrow’s sourcing managers will need to find alternative sources of raw materials to use in their processes. For example, ocean plastics are becoming an increasingly prevalent source of raw materials, which will no doubt supply future operations. This means that tomorrow’s sourcing managers will become experts on the reclaim markets.

Examples of two SCOR process categories that should be expanded beyond their current state are Return and Make.

Return processes shift and expand

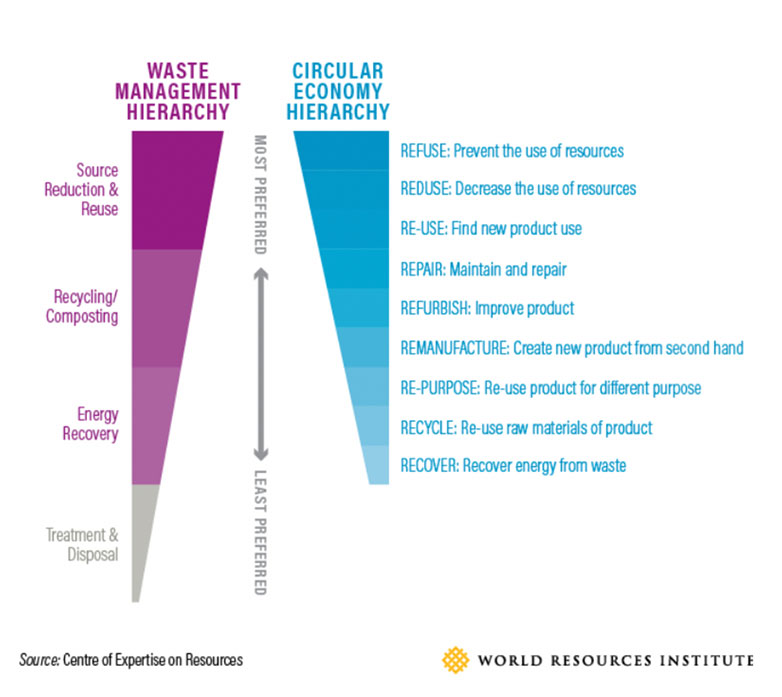

In circular supply chains, the Return process will become the Return and Reclaim process, preparing materials to be used again and again. Such preparations will include activities to reuse, repair and refurbish, remanufacture, repurpose, recycle, or recover materials, according to the Organisation for Economic Co-operation and Development. Then, these materials are complemented by any additional items needed by a buyer and can move into the next process step, Make and Refurbish.

Make processes shift and expand

The Make process will become Make and Refurbish to cover the wide variety of reusing and remanufacturing activities. This expands the manufacturing process to include the additional processes and activities required to return materials to the global marketplace in a circular economy.

Additionally, manufacturing processes will become smarter through industry 4.0 technologies. These smart processes will predict the timing, location, quality and quantity of manufacturing by-products. These by-products enter the circular economy and continue to loop through processes.

Service processes shift and expand

An additional process will become critical in the SCOR model to support circular supply chains. The idea of Service will represent the growing focus on repair and maintenance activities to keep equipment functioning longer. Service also will include the role of a product as a service. This new, flourishing category includes clothing as a service models, like Rent the Runway, and cars as a service models, such as car@go. Outcome as a service models, such as GE Aviation’s Power by the Hour, will become more relevant in industrial fields. All of these models will be enabled by industry 4.0 technology.

Shifts to the SCOR Model

The SCOR model has reflected supply chain processes, performance metrics, practices and skills for more than 20 years. It will continue to shift to reflect the supply chain habits required to support industry 4.0 and a circular economy, and supply chains will continue to strategically position organizations to succeed.

Read the entire Circular Economy blog series.

Join the circular supply chain community

- Find out about the latest news and events about circular supply chains around the world by following this LinkedIn page.

- Join a dedicated space to discuss how supply chain can accelerate the transition to a circular economy in this LinkedIn group.